On April 4, 2007, Fly Baby N101LX lost a wing while flying in

Arizona. The pilot was killed. The NTSB

report ruled that the Probable Cause was "The pilot exceeding the

design stress limits of the aircraft while maneuvering in intentional

aerobatics."

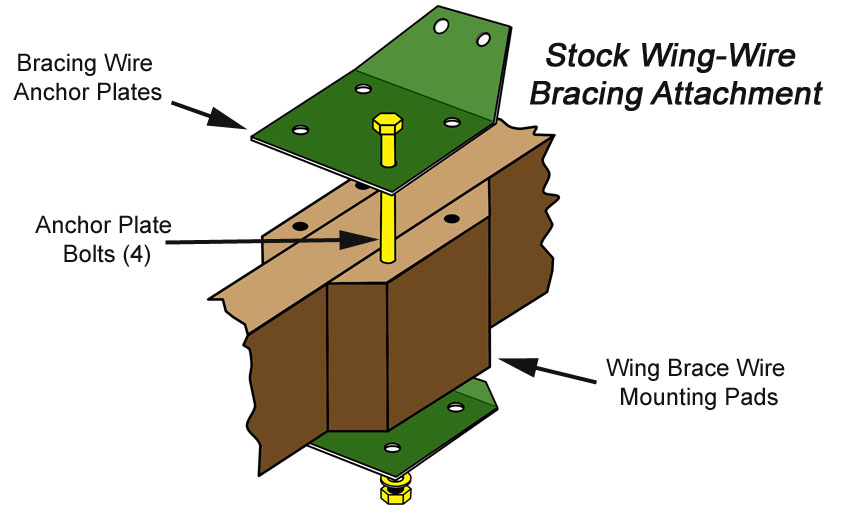

The airplane had a number of modifications, including solid bracing

wires and the split landing gear. While this immediately focused

my attention, my suspicions were unfounded. The NTSB found

no problems with them, or the wing bracing anchor plates. The

owner of the aircraft was well-aware of the previous problems.

According to a relative, the pilot had owned the airplane for more than

fifteen years, and the previous year he had removed the wings and had

the appropriate fittings "X-Rayed and chemically checked."

The failure mechanism was frankly unusual. The wing anchor plate

bolts

themselves failed. To quote the NTSB report:

I spoke to the NTSB investigator several times about this accident,

and the failure of the bolts. No previously-existing problems

were found with them... no evidence of fatigue, corrosion or

other deterioration. They failed in

overtension...being pulled too hard. With no other evidence of

casual events, the

investigator's finding was that the bolts themselves failed.

(As an aside, I had a bolt fail in my tail spring mounting system a

few years ago. Under a microscope, you could easily see a track

of corrosion from some sort of surface flaw, that let the bolt

gradually get eaten through from the inside. If the bolts on

N101LX had a flaw that led to their failure, the NTSB would have found

it.)

We don't know why the bolts were overstressed. It may have been an aerobatic maneuver gone wrong. It may have been the sudden onset of a medical emergency (the drug Amlodipine mentioned in the NTSB report is a high blood-pressure medicine), but one would assume the autopsy would have uncovered it. It may have been some other sort of failure that precipitated a high-G reaction, although there is apparently no evidence of other causes.

What I find unusual about this case is that the bolts failed at the head. To me, logic says

that failures at the thread end would be more likely

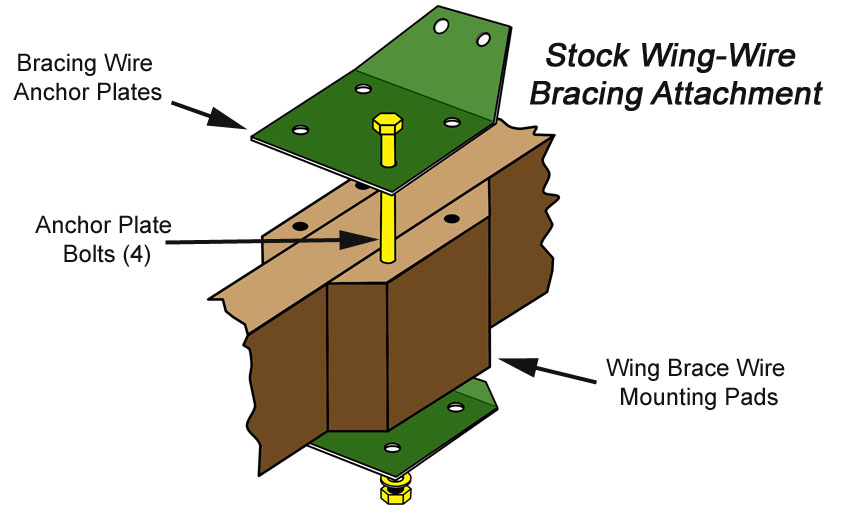

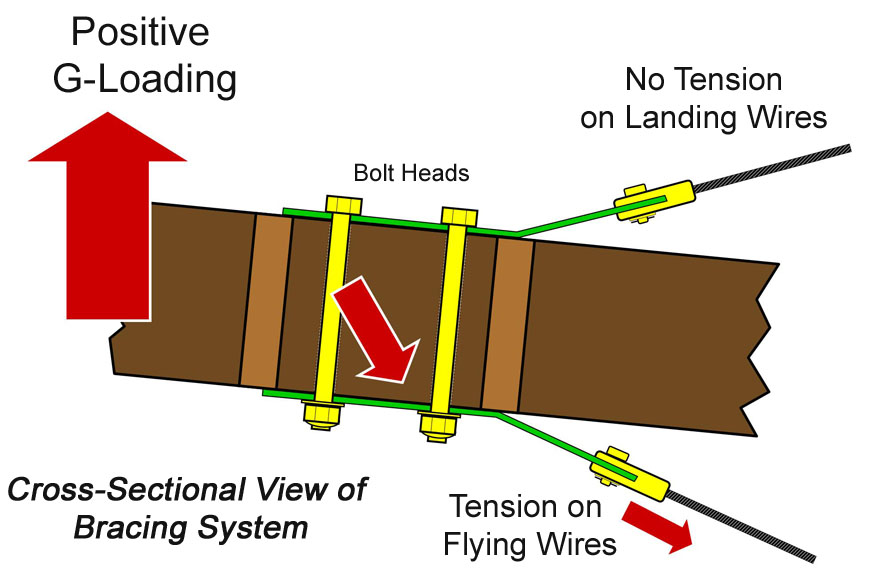

The diagram above is a cross-sectional view of the wing spar at the

point where the wing wires attach. Standard practice for

installing bolts on aircraft is to place the head

on the upper side, so that if the nut comes off, gravity will keep the

bolt in place. When undergoing positive Gs, the Landing Wires

atop the wing aren't under any load...as any Fly Baby can testify,

they're a bit slack and usually flopping in the wind.

All the flight load is carried by the Flying Wires under the

wing. The Flying Wires' tension is transmitted to the lower

anchor plates, which the vertical bolts hold in place.

However, because of the way the plates attach, it seems to me that

the plates would be applying a bit of side force to the bolts, as well

as tension. To me, then, the friction of the bolts in

their holes would relieve some of the tension on the heads and make

failure at the threaded end more likely. The NTSB investigator

said that the bolt holes in the pads were sleeved, however, so

there wouldn't be as much friction (Sleeving these bolt holes is per

plans, although Pete says it isn't required).

With some of the load on the bolt head relieved by the friction of

the side load, it seems likely that a failure of the head end of the

bolts had to be precipitated by negative

Gs...the top anchor plate had to be pulling hard on the bolt heads.

However, it doesn't seem logical that the wing was subjected to a

failure level of negative Gs. Flying upside down is one thing,

but packing on multiple negative Gs is another thing entirely.

This is not "normal" aerobatics, unless one is heading towards the

competition/airshow world. And it doesn't seem likely someone

would be practicing such in a 65-HP Fly Baby.

However, Steve Garrison, a participant in the Fly Baby email list,

had an interesting insight. Remember, the landing wires atop the

wing (which support the loads under negative Gs) are usually a bit

slack in positive G flight. This is "the nature of the beast" for

a monoplane Fly Baby; there's no cross-bracing to tighten against each

other like biplanes have). If one were pulling positive Gs in a

Fly Baby, then suddenly "pushed over" into a negative-G maneuver, the

wing will jerk downward as it shifts to having the load taken by the

Landing Wires instead of the Flying Wires. This is certainly not

ideal; the abrupt stop will cause a momentary spike in the stress in

the bracing system. If the pushover was hard enough, it seems

like you could certainly exceed the limitations of the plates, wires,

turnbuckles, or bolts.

On Page 8-1 of the plans, Pete calls for using AN3 (3/16" bolts) for

the anchor plates, but adds "If you plan extensive aerobatics,

drill for 1/4" [AN4] bolts." AN4 bolts are rated at 4,080

pounds tensile strength, vs. 2,210 for AN3 (are nearly twice as strong

as AN3 (per Table II in Mil-B-6812E).

It is unknown if the owner of

the accident airplane was aware of this recommendation; he was not the

original

builder of the aircraft. In any case, N101LX had the stock

bolts. Having bolts with twice the strength might have made a

difference.

One point which should be made. I've received email from a

cousin of the accident pilot (who is also a pilot and is building a Fly

Baby). He describes the man as an acccomplished aerobatic pilot

who had previously owned a Bucker Jungmeister. The cousin goes on

to say that the pilot was gradually increasing the level of aerobatics

in his Fly Baby...he didn't just go up and start throwing it

around. This was not

a case of an inexperienced pilot trying to teach himself

aerobatics. He was very qualified to perform the maneuvers.