[Webmaster's note: One of

the first things we learned when we started to fly was how you had to

crank on the elevator trim system every time you changed power settings

or airspeeds. I get a lot of shocked looks from folks at Fly-Ins

when I point out that my Fly Baby doesn't have a trim system... just

a metal fixed tab on the tail. The Fly Baby is so light on the

controls that, once the fixed tab is set properly, the control

pressures never get very high. I can fly touch-and-goes all day

never feeling that I'm fighting the stick.

However, as Chuck points out, the trim pressure on a Fly Baby does change during cross-countries (due to the fuel burning off). This is never more than a slight irritant...but it IS an irritant. He wanted to be able to adjust for the pressure change, and developed this nifty little trim system to let him do so.

My main point is that a trim

system is practically mandatory for most airplanes, but not on Fly Babies.

Don't think you have to add a trim system just because the Cessna or

Piper you learned to fly on had one. Chuck's system is great in

that it can be easily added after

construction...if you decide you really need one, after all. --

Ron Wanttaja]

I completed my Flybaby (N7627C) and flew it for

the first

time in September, 2008. The project

took eight years, and I thoroughly enjoyed the building and learned a

great

deal along the way. Flying a plane that

you have built yourself is extremely satisfying. I

have about 65 hours on my baby now, and

feel right at home. It’s a real blast to

fly, kind of like a flying motorcycle.

With a fixed trim tab on the elevator, my plane

flew hands

off in cruise, but I found that after about an hour in the air, forward

pressure was required on the stick to keep it from climbing due to the

reduced

fuel load forward of the CG.

Additionally, when throttling back on base, aft pressure was of

course

required to glide at a slower speed.

Stick pressures are so light on a Flybaby that this is little

more than

an annoyance, but there is something truly sublime about an airplane

that will

fly itself in all flight regimes, so I thought I’d look into adding

adjustable

trim.

Since I didn’t want to cut into my beautiful

fabric job to

install an aerodynamic system in the tail, I decided to develop a

“spring

system” inspired by one in a friend’s Piper Pawnee.

The beauty of this approach is that the

system can be entirely installed in the cockpit area, and doesn’t call

for any

alteration of the elevator controls or

cables. The system sort of rides along

on the existing walking beam located just behind the pilot’s seat at

Sta.

5.

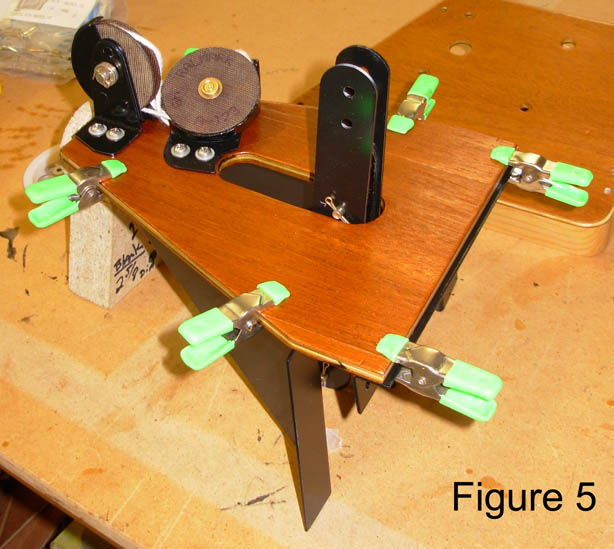

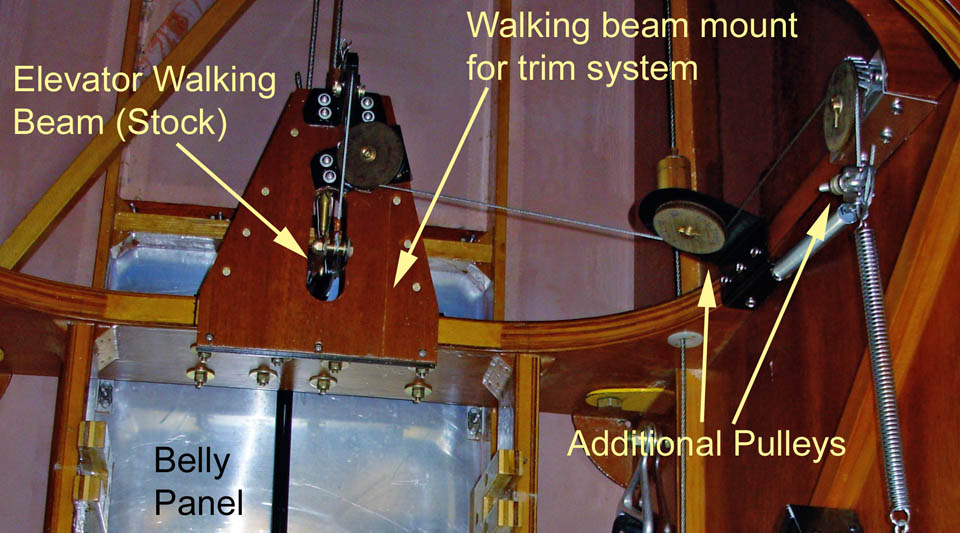

The trim system consists of three main components or assemblies. The crank box which is mounted on the port fuselage side under the throttle, the Sta. 5 walking beam mount with its cutout for the extended walking beam “ears” located just behind the pilot’s seat, and the two directional pulleys that lead the cable from the walking beam mount to the crank box. (see fig. 1 for a picture of all components).

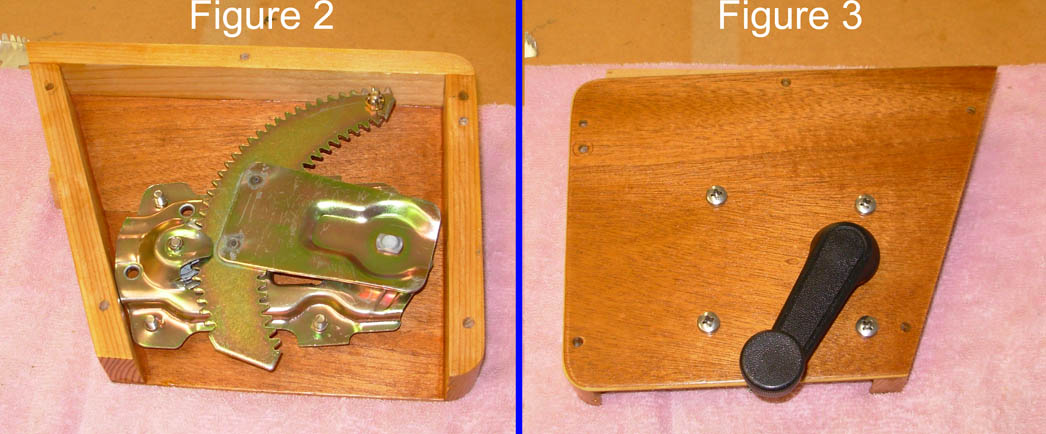

The crank assembly ( fig. 2) is simply a 1/8”

plywood box

with spruce framing sized to hold a 1976 Datsun pickup truck window

regulator. You can find new

aftermarket

regulators on the internet for about $20 – just saw off the part you

don’t

need. I’m sure any number of regulators

would work, the Datsun one just looked to be about the right size, and

was. (

fig. 3)

There is room next to my left leg to crank the handle,

and it is low

enough not to interfere with the throttle (Figure 4)

There is room next to my left leg to crank the handle,

and it is low

enough not to interfere with the throttle (Figure 4)The third component, for lack of a better term,

consists of

the two directional pulleys mounted on the Sta. 5 vertical that route

the cable

to the crank box. Since the lower of the

two mounts stands off more and is less supported than the other mounts,

I made

it out of chromoly – the others are aluminum.

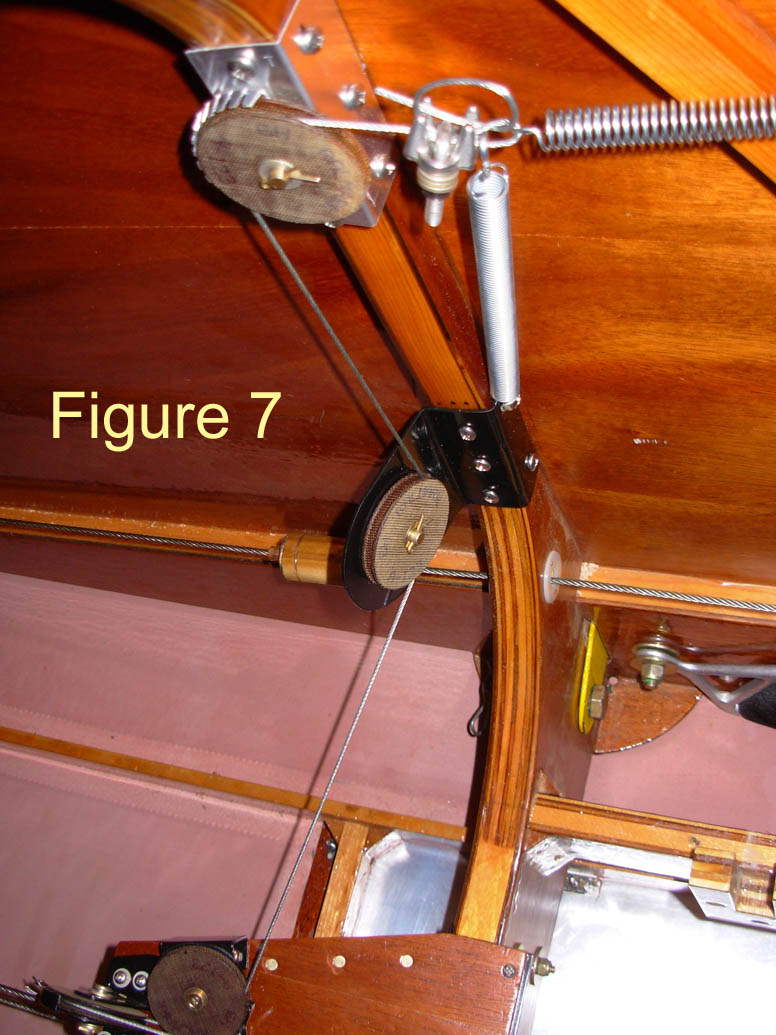

The springs are the final touch – you’ll see that

there are

two. (fig. 7) The horizontal (trim)

spring creates the tension that raises or lowers the nose when you

crank the

crank. (You need a spring in the system

as opposed to just a solid cable so that you can override a trimmed setting to dive or climb from the

trimmed position – think about it a minute.)

The vertical spring’s only function is to take up any slack in

the cable

when the nose is trimmed way down and the stick is pulled all the way

back. This is a safeguard against

the

cable jumping the pulleys, perhaps not really necessary with the pulley

guards

in place. I did not put an opposing

spring in the system for nose down trim, although this could be added. Instead, I have set the existing fixed tab on

the elevator to provide the nose down force just necessary for level

flight

when getting very low on fuel – this proved to be a very slight

deflection of

the tab, so not much drag. (Or at least

not enough for me to go to the trouble of figuring out how to mount a

second

trim spring) I tried a couple of springs

before I found the one that was just right to serve as the horizontal

trim

spring – it came from Home Depot. The

one that proved to be just right has a pull of about 3.6 lbs, the first

one I

tried at 2.1 lbs was too light. The

vertical spring can be very light, as again it just takes up the slack

when

there is no pull on the cable. Given a

Flybaby’s light stick forces, the trim spring is only required to exert

a

moderate pull and is easily overridden even when the aircraft is

trimmed full

nose up – an important consideration.

For a Flybaby that has a belly

panel like mine, this is a

very doable project. I was able to work

from a creeper below, and then from the top by sitting backwards in the

cockpit

on the floor. By the way, the Pawnee

system utilizes a cable that runs directly from the crank box all the

way back

to a spring on the elevator horn, but it’s so tight back there in a

completed

Flybaby that I thought working with the walking beam was the way to go. The walking beam approach is necessarily more

complex, but there’s plenty of space to work in, and you don’t have to

cut into

anything.

How does it work?

Like a champ. As the fuel burns

off, just give it a crank forward, and it settles back down to level

flight. Crank it back a turn or two when

you reduce power for base, and it comes down hands off at 65 mph likes

it’s on

rails. Don’t you love an airplane that

will do that?

Disclaimer: The

foregoing is provided only as information that may be of interest to

Flybaby

owner/builders. I am just a builder, not

an engineer. If you intend to utilize a

system based on this approach, I would

suggest having it inspected by an A&P with Inspection

Authorization, or at

least an EAA Technical Inspector.

June 2009