When I rearranged my panel this year to incorporate the ICOM handheld as a permanently-mounted radio, I noticed that my compass was no longer pointing true. In this picture, for instance, the plane is pointed North, and you can see the compass pointing at about 330 degrees.

Admittedly, the

plane's in a metal hangar...but it didn't point that far off, before.

Don't know whether that was due to its change of position on the panel

(closer to the aluminum forward turtledeck), the loss of the nearby mass

of the VSI, or the addition of the insignificant mass of the ICOM, but

the needle was now pointing significantly off from the actual magnetic

heading. The FAA gives you ten degrees' tolerance, but I was well

over that.

My annual's coming up next month. Last year, the A&P reminded me that I didn't even *have* a compass correction card like I was supposed to. I hadn't re-installed the card, after the panel re-do, but it's obvious the old card would be way off.

So... time to re-swing the compass.

Unfortunately, on reading the procedures, I saw a lot of potential problems.

The basic procedure is to point the airplane towards magnetic north, adjust the compass N-S setting so it read 000 degrees, then turn towards magnetic east and play with the E-W adjustment. Then point south and take out *half* the error, and do the same for west. Then rotate the plane in a circle, stopping at 30 degree increments and logging the compass reading at each heading.

Not too difficult. The problem was all this was to be performed as if the airplane in level flight attitude with the *engine running*.

(BTW, the EAA has a reprint of a Tony Bingels article on compass swinging if you've registered on their web site.

I could see a bunch of difficulties with this. First, I didn't like the idea of trying to support the plane with its tail up and the engine running. There's not much weight on the tail in level-flight attitude...I was worried it might blow over with the wrong wing gust...or the shaking involved in running the engine might make it slip off the tail stand.

Second, the swinging procedure required the plane to be repositioned sixteen times. I wasn't sure that my back was up to picking up the tail and moving it sixteen times, while trying to ensure it was pointed in an exact direction when it was set down.

Third, I didn't like the idea of starting and stopping the engine so many times. That new starter clutch cost me about $400, and I was loath to exercise it when I didn't have to.

Finally, I *knew* my knees wouldn't be up to repeated crawl-ins and crawl-outs of the cockpit to reposition the tail.

To add to the problem, one needs a compass rose painted on the asphalt...which my home airport doesn't have. So any equipment I needed to perform the procedure (tail stands, sandbags to help hold the tail down) would need to be loaded aboard the airplane and flown to a nearby airport to perform the procedure.

It's easy enough for aircraft manufacturers...they build custom compass-swing platforms, with built-in tiedowns and a crew of people. In my case, it was just me and my wits. Half-armed, at best.

I'm normally not one to shortcut vital maintenance procedures, but I was pretty much sure that compass swinging wasn't one of them. It was different, back when I was a student. The VOR was great for flying to big airports, but for going to the little places in the North Dakota prairie, I needed a chart, plotter, flight computer, and a reliable compass.

The Citabria I learned to fly it had a dead-simple VFR panel, with just a turn-and-bank beyond the required instruments. But I still had to fly the under-the-hood section of the Private Pilot flight test, so my instructor had taught me all the intricacies of precision turns by compass...it turned too fast when turning in one direction, so let the lubber line pass the target and start the rollout ~20 degrees past the desired heading. In the other direction it turned too fast, so start the roll-out 20 degrees too early.

But things are different today. I live in a place where ~10,000 foot mountains provide navigational beacons from the International border to Portland. I almost never fly in anything but solid VFR conditions. For cross-countries, I've got a $100 satellite navigation system that points an arrow directly at where ever I want to fly (assuming I programmed it right, of course...).

I could picture a Marine drill instructor screaming in my face, "YOU TAKE CARE OFF THAT COMPASS, MAGGOT! IT MAY SAVE YOUR LIFE ONE DAY!" but I just couldn't imagine a situation where my life would be forfeit if the compass read, say, 120 degrees when it was supposed to read 125. If I get caught without ground reference, I'm dead...ain't no blind-flying instruments in my Fly Baby.

Instead, I decided it was time for a Hillbilly Compass Swing. I needed to derive a way to get the most accurate compass adjustment for as little hazard and knee-and-back damage as possible. The FAA requires the compass be within 10 degrees of the correct magnetic heading; this gave me a budget to work within.

So. Time to stand back ,chewing on a grass stem, with my thumbs hooked in my bib overalls, looking at the airy-o-plane and doing' a heap 'o thinking.

First thing, I'd drop the level-flight attitude. Yes, that would add a bit of error. But the 'baby only sits pretty flat. Can't believe it would use that much of that 10-degree budget.

Second... drop the engine-running aspect. I'd watch the compass on my next engine start, see if the compass swung much.

Third... I'd eliminate the flight to the airport with the painted compass rose and use my own method. I honestly don't think I could align the aircraft all that accurately with a compass rose painted on the ground below. I'd certainly be lucky to get the pointing to within five degrees of the rose.

How to check the actual magnetic heading, though? Obviously, a compass. One big thing I had working in my favor was having a wooden airplane. I'd use a simple lensmatic camping compass to set my alignments.

Now, to prepare. Open the adjustment panel on the compass. I didn't have the required non-magnetic screwdriver, but I figured on tweaking the adjustment screws, then pulling the screwdriver away before believing the compass reading.

I tried the compass on the wingtip, but realized it was too close to the flashing along the leading edge. I settled on the aft turtledeck, halfway between the metal baggage area and the start of the vertical stabilizer. The position was perfect...I'd be positioned right at the compass when it came time to push the tail around.

The space between the top two stringers was just a bit wider than the compass... it was easy to eyeball the positioning, and then tape the compass in place.

Roll the plane outside, radios on, then push the tail over to unlock the tailwheel. Station myself by the lensmatic compass, and start pushing the tail over to align the plane with magnetic north. A problem here...the lensmatic compass was a bit sticky. I took to tapping it to free it, as I nudged the tail around.

Got it reading "N", then checked the surroundings. Nuts. I knew Seattle had a 20-degree variation, and I knew the airport was aligned with true north. But the plane was pointed about 30-degrees off true north.

Damn. I looked at the lensmatic compass again. I tapped it, and it swung a few degrees and stopped.

Obviously, the tail-down attitude of the plane and the natural downward slope of the turtledeck were too much for it. It needed a more level mounting.

Back to the hangar, grab a couple of small pieces of wood. Prop a ~1/2" chunk under the aft end of the lensmatic compass and re-tape it. It then swung freely. Nudge the tail until it read "N", then look. Yep, about 20 degrees off true.

(I didn't realize

that the compass' little wire bail could be used to set the angle, as this

picture shows. I didn't need the wood....)

(I didn't realize

that the compass' little wire bail could be used to set the angle, as this

picture shows. I didn't need the wood....)

To the cockpit to adjust the N-S settings on the compass. I'd heard the adjustments were real sensitive, so I put the screwdriver in place and turned the adjustment screw a couple of degrees. I pulled the screwdriver away. Nothing. I turned it a bit more. This time, it did change a bit. So I cranked on the screw, and the compass swung toward the "N" mark.

Then ANOTHER source of error hit me: Parallax. Where I was standing, outside the cockpit, did not put my eyes in the same position as where they would be in the pilot's seat. Hence the lubber line, a bit above the compass dial, would appear to be in a slightly different position depending upon one's head position.

I leaned forward, and tried to position my head as close as possible to the in-cockpit position. Tweak the N-S screw a bit more, get it reading close to North. I'd have to remember to position my noggin at the same place, every time.

Then back to the tail. Push it around towards east. Turns out the lensmatic compass' position on the turtledeck was perfect...I could lean directly over the compass, gently nudging the tailcone back and forth until the compass line was right on the desired heading.

Back to the cockpit, Adjust the E-W setting.

Push the tail around to South. Check the aircraft compass. The instructions said to take half the error out...but the compass was just two degrees or so off. Close enough. Same at the West reading.

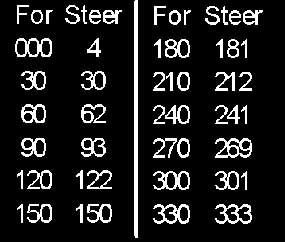

So...time to log

the values around the entire circle. I went to the tail, and pointed

the plane North again. To the cockpit, log the aircraft compass reading.

Push the tail to 30 degrees, log the aircraft compass. Then to 60,

to 90, to 120, etc. all around the compass rose. No reading more

than four degrees off that indicated by the lensmatic compass.

So...time to log

the values around the entire circle. I went to the tail, and pointed

the plane North again. To the cockpit, log the aircraft compass reading.

Push the tail to 30 degrees, log the aircraft compass. Then to 60,

to 90, to 120, etc. all around the compass rose. No reading more

than four degrees off that indicated by the lensmatic compass.

Push the plane around back to North, and re-check the N setting just to be sure. Only *one degree* off my starting value! So at least my results were repeatable.

Next step was to print out a correction card on label paper and stick it on panel.

With the difficulties involved in trying to push a plane around to line it up with painted markings with its tail propped up, I doubt my results are *that* far off the actual readings.

I'm sure there'll be some that'll cringe at the short cuts I took on this process. As a Systems Engineer, and a former test engineer, I'm a bit cautious, myself. But I really think this method got me within the FAA's ten-degree limit. I've done some in-flight checking, and it seems pretty good.

Of course, if I leave for California and end up in Ireland, you'll all know what to blame. :-)

Ron Wanttaja