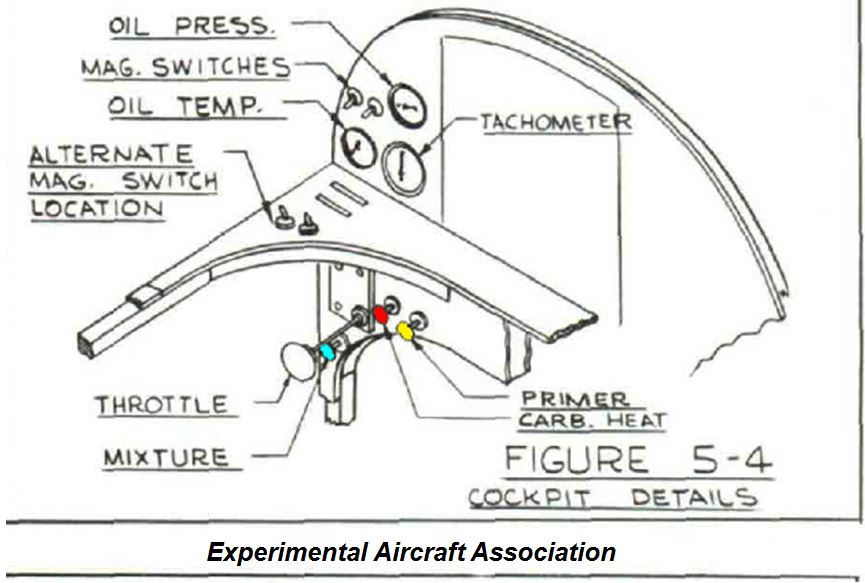

One would assume that Pete built N500F this

way. The trouble is, by the time *I* was flying it,

the carb heat and the mixture controls had switched

places! Had Pete built it that way all along...or had

it been swapped during the plane's restoration in 1982?

Could be either way.

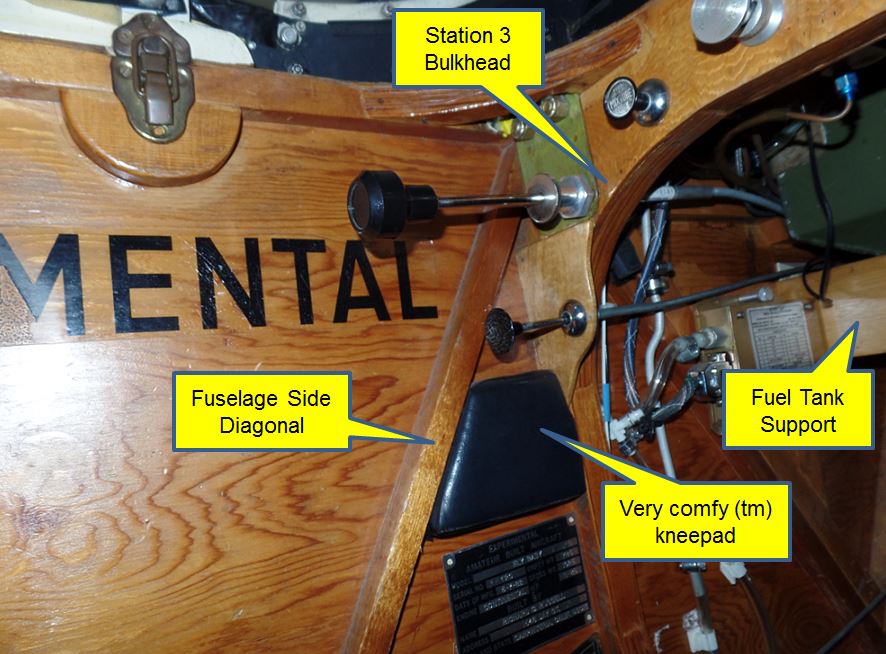

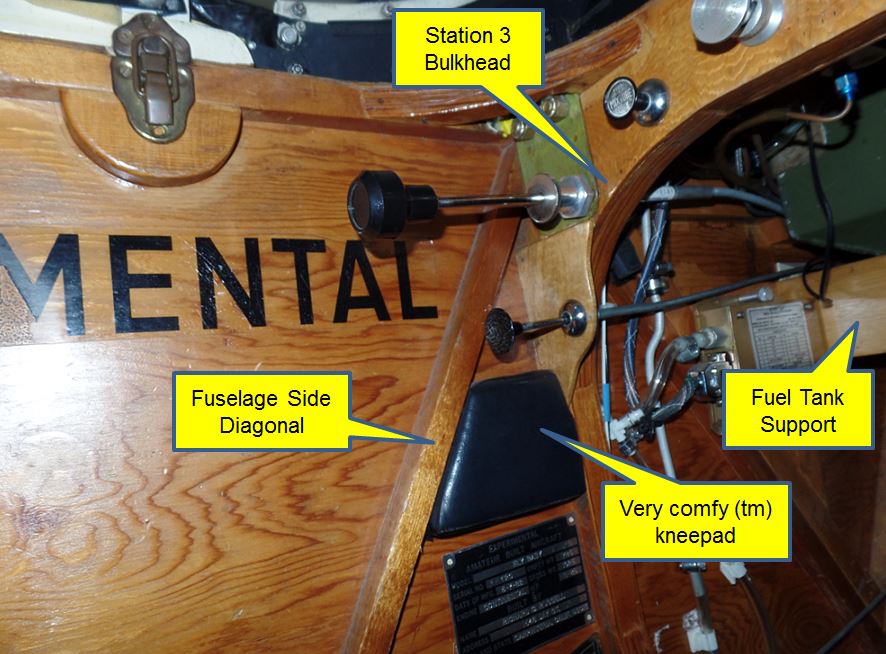

The one sort of marginal thing here is the location Pete

shows for the mixture: It's *right* on the edge of the

inner curve of the STA 3 bulkhead. Take a look at this

close-up of my cockpit sidewall.

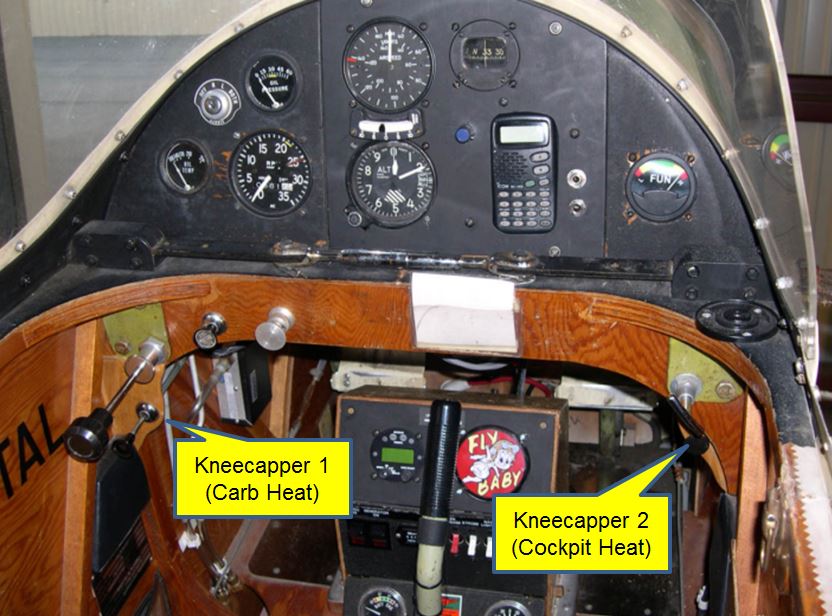

Notice the carb heat on its Kneecapper

support...and the relative position of the diagonal on

the fuselage side. Obviously, if the carb heat had

been positioned on the STA 3 bulkhead, there would have

been a chance that the fuselage diagonal wouldn't have

let the knob come out all the way.

Apparently, you CAN position the knob successfully

there...probably if you put it *right* on the edge of

the bulkhead. But the builder of my plane didn't

like the looks of it, and installed the carb head

control on a 1/4" plywood extension glued to the STA 3

bulkhead.

Note, also, the Very Comfy (tm) kneepad just below the

carb heat control. The previous owner of my plane

had been about eight inches shorter than I; the pads

were probably ideally located for him. However,

with my towering six feet of height, my knees hit the

damn plywood support, instead. This was very

uncomfortable. And, of course, it was like that on

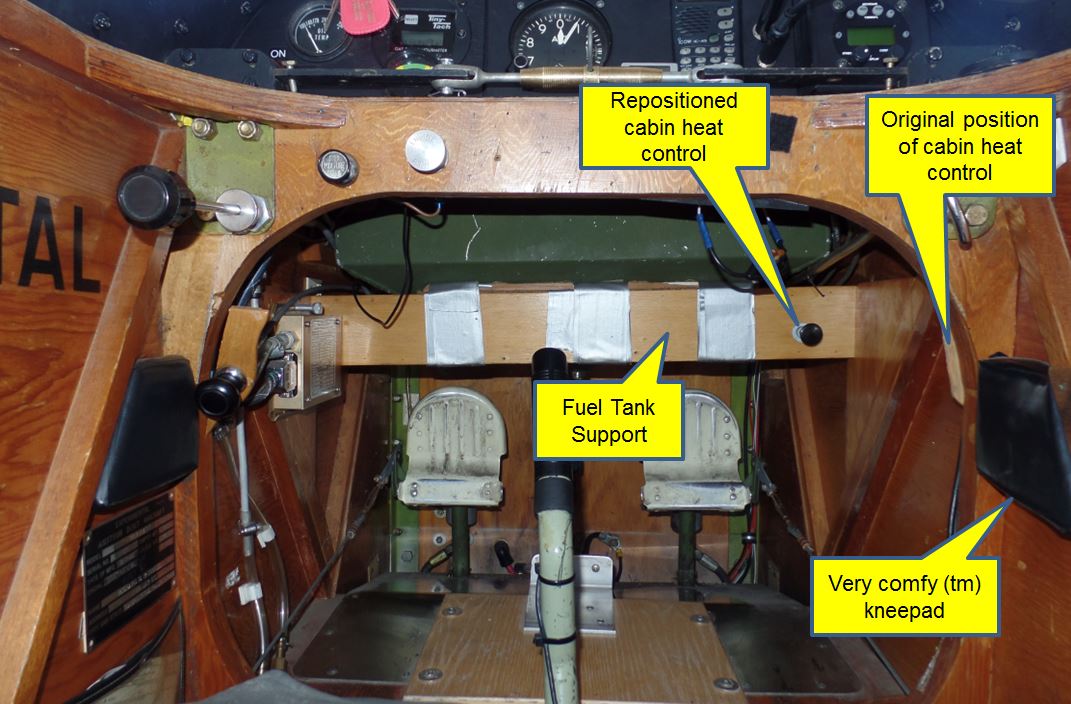

BOTH sides, with the cabin heat control on the opposite

side (albeit on the other side of the bulkhead). I

had previously removed this one, moving the control to

the bulkhead supporting the fuel tank.

Even worse, the two kneecapper plates had been installed

with sharp edges pointing inward. One of the first

things I did after buying the airplane was to carve a

curve into the inward-facing sides of both plates....as

you can see in the above photo.

The Repair

So, how to fix it.

I'd like to have put it smack dab in the same location N500F

had it. But...was concerned about clearance (like the

original builder) and I would have had to strip the entire

old plate off the bulkhead to have any chance of making it

work. Plus I'd have to drill the new holes with the

diagonal potentially getting in the way.

Move it to the fuel tank support bulkhead, like I did the

cabin heat control? Would work...but the area itself

is out of sight from the pilot seat. The carburetor

heat control is pretty important on a Continental; I didn't

want to have to fumble under the panel to work it.

Cabin heat gets turned on in the fall, and off in the

summer. Doesn't get a lot of work, doesn't hurt it

it's out of sight.

So the ideal solution would be to move it to

the lower edge of the top side of the Station 3 bulkhead,

alongside the mixture and the primer.

Two problems there. First, there's not really a good

spot for it. If you look at the first image on this

web page, if I were to install the control equally spaced

with the others, it'd be nearly center in the cockpit...and

a good foot from the throttle. That's bad cosmetics,

and bad human factors. On a Continental, the carb heat

knob should be turned to "hot" before ANY power

reduction. Better to have it close to the throttle.

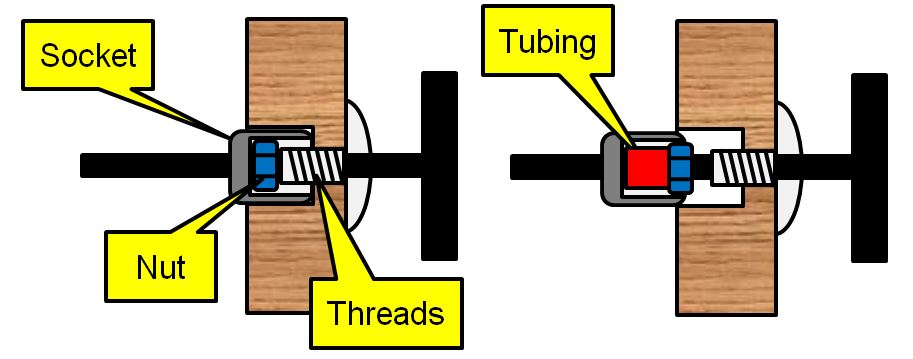

The other factor is the difficulty in making a new mounting

location on the STA 3 bulkhead of a completed

aircraft. The control itself is designed to go into a

~1/2" thick panel, yet the STA 3 bulkhead is a sandwich

that's about an inch wide. Just drilling a hole for

the control won't work, one has to go behind the bulkhead

and rout out the back of the bulkhead, as the diagram to the

right shows. And that's just too tough to do, with all

the structure, wiring, and piping of a completed aircraft.

The solution: Install the carb heat knob where the

mixture control is located.

What to do with the mixture? Remove it entirely.

Now, some of you are probably going through the roof.

"You need it to kill the engine!" "You need it to

optimize the mixture for altitude!"

Allow me to point out that my aircraft has a Stromberg

carburetor. They were pretty much standard equipment

on Cubs and Champs.

And on these airplanes, the mixture control was an

extra-cost

option...one that not every purchaser chose to have.

"Wha....."

It's pretty simple: The Stromberg actually doesn't

adjust very far. In fact, one cannot shut down the

engine using the mixture...it doesn't lean it out enough!

Altitude-wise, the mixture on a Stromberg doesn't start to

work until one gets above, say, 5,000 feet. And,

despite living in the shadow of the Cascade and Olympic

mountains (on clear days, I can see three volcanos from

pattern altitude), I rarely fly much above 3,000 feet.

So, I removed the mixture control, and ran the carb heat

control in its stead. My A&P would be coming by to

perform the Condition Inspection, and I had him wire the

Stromberg full rich.

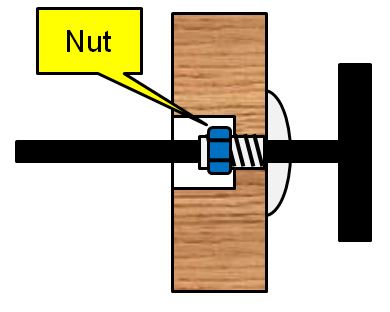

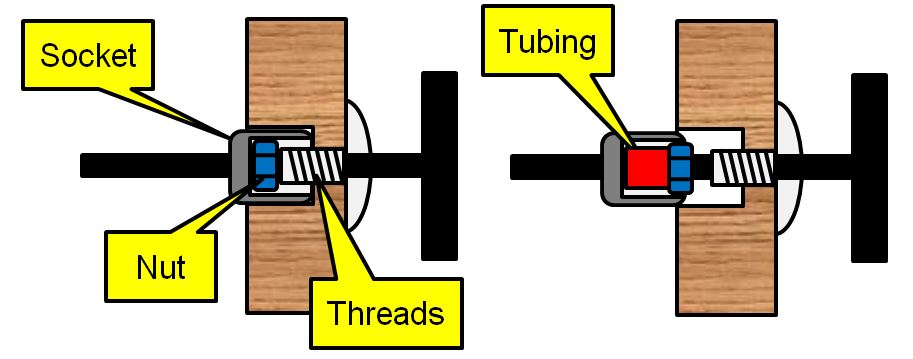

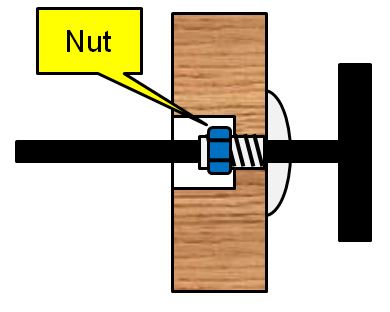

Hardest part was getting the nut started to attach the

control itself. As I mentioned, the mounting location

is recessed due to the thickness of the bulkhead. I

slide a socket over the sheath for the carb heat, holding

the nut, slid it up to the mounting location, and tried to

get the nut engaged on the threads. The trouble was,

the socket was too deep to actually shove the nut against

the threads so it could attach.

My solution is on the right... a short piece of tubing

between the socket and the nut to shove the nut hard into

the threads.

Upshot

The hardest part is getting used to the new carb heat

location. My airplane's was located below the

throttle, in approximately the same location N500F had

it. Was pretty darn used that location, and the new

location threw me off. I'd reach down for the carb

heat and find myself caressing my left knee.

Which was resting, quite comfortably, on the Very Comfy (tm)

kneepad.

It's been a couple of months, and I'm starting to get used

to it. It's too bad I

had to do the

change, but I'm happy with it, now.

So the ideal solution would be to move it to

the lower edge of the top side of the Station 3 bulkhead,

alongside the mixture and the primer.

So the ideal solution would be to move it to

the lower edge of the top side of the Station 3 bulkhead,

alongside the mixture and the primer.