No, this isn't a primer on how to party with a bunch of carrier pilots.

A lot of Fly Babies don't have electrical systems or starters, and must be hand-propped. Hand-propping isn't that tough or dangerous...it's pretty easy, and you can always count on some shocked attention from other pilots in the vicinity.

It's funny to consider, but most hand-prop accidents don't involve the person losing their footing or whatever and falling into the spinning prop (though it *is* a hazard to watch out for). Most hand-prop accidents involve the airplane getting loose and hitting something.

It's vitally important to secure the airplane when you're hand-propping. Attach tiedowns, use chocks.

However, after the engine's running, there's that awkward moment where you untie the last rope or remove the last chock, and you have to trot into the cockpit before the plane starts rolling away.

The

best

solution for hand-propping is a remote-release tail hook.

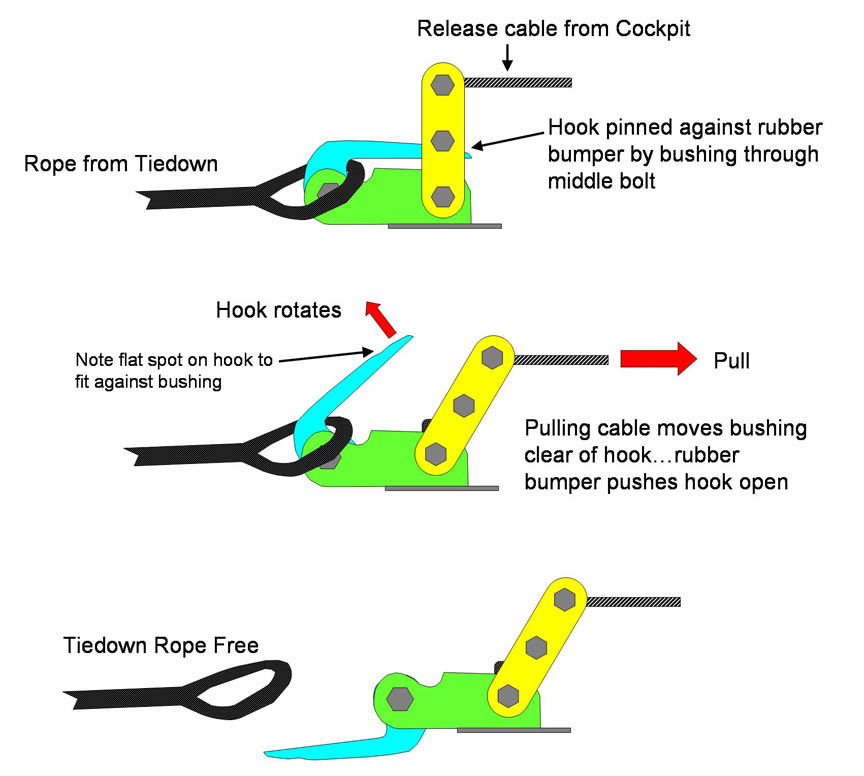

This allows you to tie a loop in a tiedown rope, slip it into the

hook, start the engine, climb into the cockpit, and release the

tail hook by pulling a handle attached to a cable.

The picture on the right is the hook on N500F, the prototype Fly Baby. This is a sailplane release hook, installed by Pete during the 1960s and actually used to tow sailplanes for one weekend. Pete had requested a sailplane tow waiver from the local FSDO. The inspector granted it on Friday, and Pete spent the weekend towing sailplanes with the Fly Baby. But when the FDSO inspector got in Monday morning, he started digging into the stack of backed-up material in his in-basket...and found a notice that FAA Headquarters had decided to ban sailplane-tow waivers for homebuilts!

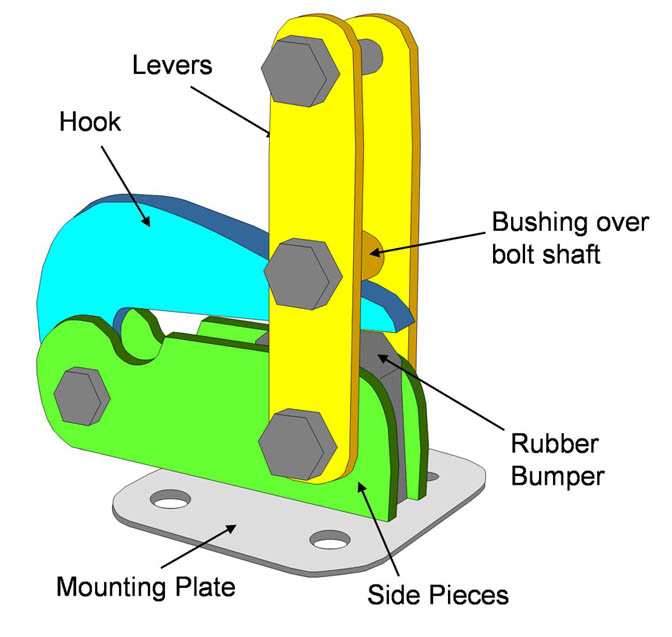

Anyway, the hook above is a commercial unit, available from places like Wag-Aero. Unfortunately, they charge about $250 for one of these. I've seen a number of Fly Babies and other homebuilts with scratch-built release hooks. They all seem to work OK. They basically have to be strong enough to withstand the thrust of the engine at full throttle (about 500 pounds or so), yet release with a fairly gentle tug on the cable.

Here's an illustration of how they work:

The nice thing is that they DON'T have to be desiged to be easily releaseable at full load. If you've accidentally started the engine at full throttle, take it from me: you'll throttle that thing back down as quickly as you can. Been there, done that, and am enduringly grateful that the tail hook and the tiedown rope held for the ten seconds or so it took to reach the cockpit.

Here's a photo of a homebuilt tailhook used on the Story Special. Like just about all of these kinds of hooks, it's bolted to the tailwheel bracket: Unlike the commercial one above, though, the hook opens horizontally instead of vertically. This eliminates the need for welding.

Whatever type of hook you install, you'll need some way of activating the release. Most builders run some sort of cable from a handle in the cockpit. Mike Proshold, on the other hand, uses a clip to the tailwheel control horn. As you can see from the next picture, Mike's hook is off-center a bit to give the release chain a straight shot to the horn. The chain connects to the norn with a c-clip selected so that it releases at a moderate level of tension. All Mike has to do is press his left rudder pedal...the horn turns forward, tightening the chain until the hook releases. As the rudder keeps moving, the tension eventually overcomes the capabily of the C-clip and the whole chain drops free of the rudder horn.

Obviously, this setup has to be carefully balanced to ensure the clip doesn't stay connected and mess up the rudder control. It's probably a bit safer to keep it isolated from the rudder system and run a separate cable, but Mike's hasn't given him any problems.