A Radio-Controlled Fly Baby For Less than $40

June 2007

Back when I was a kid, I got into the U-Controlled gas-powered aircraft.

These were cheap, and I could build a new one out of a buck or so of balsa

wood and transfer my trusty Cox .049 to the front (or back, depending on

what I was up to).

What I REALLY wanted to do is get into those radio control models. THAT

was more like really flying.

But the cheapest plane back then cost $150 (for one that just had rudder

control), including the radio gear, and you'd have to buy a $50 engine

as well. That was absolutely a ton of money to me back then...about

a year's worth of my paper-route profit. Plus, the planes were made

of balsa and tissue paper. Hundreds of hours to build. One

false move, one rookie mistake, and POOF! It was all gone.

If the radio gear failed for some reason, you'd even get to watch your

expensive RC plane disappear to the far horizon, as the gas engine kept

running and running.

So for forty years, I dismissed the thought of flying Radio Controlled

airplanes.

And in that forty years, the sport changed tremendously. Electronics

have gotten much, much smaller and lighter. Battery technology has

produced lightweight high-power batteries than can be put to work spinning

electric motors to replace the cranky gas ones. The telecommunications

industry produces little tiny motors used for the "vibrating" modes of

phones and pagers. And the chemists have produced durable, flexible,

high-impact foam plastics for a variety of uses.

This has produced what the RC'ers call "Foamies": Tiny radio-controlled

aircraft that are dirt cheap, sold ready-to-fly, and almost impossible

to break. The prices run about $30, less on-sale. That's probably

close to what my old U-control models would cost to build, today.

That $30 includes everything...the aircraft, the motors, the transmitter,

the receiver, and the batteries onboard the aircraft. The only thing

you have to buy is the AA-cells for the transmitter.

The airplane batteries charge via a connector from the transmitter,

so you don't need a separate charger. The planes ONLY operate if

they're receiving a signal from the transmitter. If the plane goes

out of range, the motors automatically shut off and the plane glides down.

Probably the best example of the breed is the "Air Hogs Aero Aces."

You can find those at any toy store, and most of them fly pretty good,

once you get them balanced out.

These cheap RCs don't quite fly like conventional aircraft. There's

no aerodynamic controls...there are two motors mounted on the wings, and

your control system just adjusts the power to the motors. Throttle

full forward, the plane climbs. Stick right, and the left-side motor

turns faster and the plane turns. It doesn't let you do aerobatics

(at least not deliberately...) but it's easy to pick up how to fly them.

Even better, they're fairly slow...you can fly them in a large back yard.

I bought a

few of these planes, then discovered the new Tyco "Sky Force" line of mini-RC

planes. The interesting thing about these is that the airplanes are

just profile designs (e.g., the fuselage is flat, not three-dimensional)

like my old U-control planes, and the airplane's RC gear is modular.

The receiver and battery are installed in a tiny plastic box that clips

into a special mount on the side of the airplane, and two sets of wires

lead to the motors, which clip onto special mounts on the wings.

The Sky Force sets include one set of RC gear and two airframes...and you

can quickly switch the receiver and motors to the other airframe as you

wish.

I bought a

few of these planes, then discovered the new Tyco "Sky Force" line of mini-RC

planes. The interesting thing about these is that the airplanes are

just profile designs (e.g., the fuselage is flat, not three-dimensional)

like my old U-control planes, and the airplane's RC gear is modular.

The receiver and battery are installed in a tiny plastic box that clips

into a special mount on the side of the airplane, and two sets of wires

lead to the motors, which clip onto special mounts on the wings.

The Sky Force sets include one set of RC gear and two airframes...and you

can quickly switch the receiver and motors to the other airframe as you

wish.

Which means that the system is ideal for making your OWN radio-controlled

airplane. Such as a Fly Baby!

Which is, of course, exactly what I did. It's got a wingspan of

about 16 inches, and weighs a bit over an ounce, ready-to-fly (about 32

grams).

The Sky Force planes are made out of sheets of a plastic/foam called

Depron, and I made the Fly Baby out of a sheet of 3 mm Depron purchased

at a local hobby store. You could probably make the fuselage out

of 1/8 balsa and the wings out of 1/16, though going a 1/32" thinner for

both would be even better.

If you use the Depron, you'll need foam-safe superglue. This

is usually only available at the hobby stores, but it's also sold as "odorless

superglue" at other locations. The odorless is the key to the foam-safe

variety. If you use the balsa, the regular gel-type superglue will

be fine. I'm told that Elmer's glue works on the foam, too, but take

a while to dry.

First off, buy a Sky Force kit, assemble either the "Fire Rescue" or

"Biplane" airframes, install the radio gear, and get some flying practice

in. These planes are pretty durable, and you want to learn to fly

on something other than your Fly Baby. You'll eventually have to

cannibalize either the Fire Rescue or Biplane for receiver and engine-mounting

parts, so you might as well get some wear and tear on them.

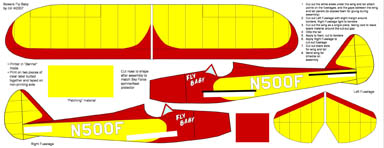

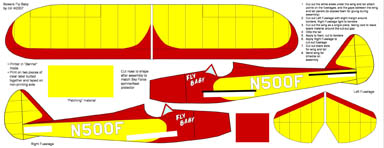

Next, download the file the image below links to:

Right-click on it, and select "save". You'll get a file called

"Fly Baby SF.jpg". If you get

one with "_TH" after the "SF," you've accidentally grabbed the thumbnail

above.

The file contains the templates for all the Fly Baby parts. You'll

need an ink-jet printer than can print longer than a single sheet of paper

(e.g., has a "banner" mode). Butt two sheets of paper end-to-end,

tape them together on the back side, and run them through the printer in

the banner mode. I told my computer that I was using a custom 8.5"

x 22" paper size, and it printed it without a glitch. Biggest drawback

is that the ink is water-soluble...keep the plane out of puddles!

There's actually two ways you can do this. First, you can use

plain paper to just make templates to transfer to the Depron. Or,

pick up a pack of clear full-sheet label material from the local office

supply store. This material is fairly light, and lets you transfer

graphics to the plane (like the photo above) rather than just end up with

a blank white airplane. Instructions are on the sheet. Apply

the label material to the depron, then use it as patterns to cut

out the parts. The hardest part was applying the second side of the fuselage,

since I just had to kind of eyeball it in place.

Now you start cutting up one of the existing airplanes. Start

by removing the combination spinner/gray plastic keel protector from the

front of either the Fire Rescue or Biplane. Take them off as one

unit...these protect the front of the plane and provide stiffening for

the fuselage.

Cut the fuselage apart and remove the rectangular plastic ring for holding

the receiver. Place the fuselage flat on the tabletop, position the

receiver on the forward fuselage as shown in the photo above (actually,

set it a bit further forward, if you can...the stock plane has an aft CG

problem), and press gently on the fuselage. It will leave a bit of a dent

on the fuselage depron. Use an exacto knife to cut out the shape, then

trim it as necessary to get the receiver mounting ring to slip into the

fuselage. You'll need to cut additional notches out, top and bottom, for

the clips on the receiver box to mount top and bottom.

Take the old Sky Force fuselage you took the spinner/keep reinforcement

from, place it atop the Fly Baby fuselage, and trace out the shape needed

to fit the spinner/keel assembly. The assembly should press-fit to

the Depron; if it doesn't, use a bit of wide clear packing tape to hold

it in place.

Cut a 1/2" square notch from the trailing edge of the wings, just outboard

of the second rib line (see the photo). Cut the wing slot and horizontal

tail slot on the fuselage. Slide the wing into place, and bend it

up a bit to give it some dihedral. Apply glue..

While you're waiting, take the wing from your Sky Force plane.

You'll notice the engine mounts have tape reinforcing the attachment to

the wings. Take a pair of scissors and cut out the engine mounts,

INCLUDING the wing areas with the reinforcement. You aren't removing

the engine mounts from the wings, you are cutting away sections of the

wing itself. Cut away a bit extra wing...it helps.

If you are cutting up the Fire Rescue plane, the engine mounts go underneath

the same wing you cut them away from. Position them so that the slot

is approximately lined up with the trailing edge and parallel with it.

Apply that wide clear packing tape on the bottom to hold.

The Biplane actually installs the engines differently, so you'll have

to use the right mount on the left Fly Baby wing.

In both cases, the engine mounts are installed at what appears to be

a slant...there's the round part where the motor goes, and the narrow end

points towards the forward fuselage. See the original Sky Force wings

(you'll still have one uncut set left) for an example.

When all the glue is cured, install the receiver and motors (the motor

with the red-and-white wires goes on the right wing) and take it out for

a test glide. If it noses up and stalls, bend down the tailing edge

of the horizontal tail. You might have to add a little weight fore

or aft, depending on how your plane came out.

Then charge up the batteries and turn 'er loose.

Here's a video

showing mine flying.

There are two frequencies available in the Sky Force system (27 MHZ

and 49 MHZ) so you and a buddy can fly at the same time. You can

tell which you're getting by looking at the "altimeter" on the right side

of the box front.

One hint: The Sky Force system seems to suffer from some problems

with radio range. One way to help is to increase the length of the

receiver wire on the airplane. Strip a short bit of insulation off

the end, then solder on another piece of wire about the same length.

Find as fine a wire as you can...Radio Shack sells some #30 or #40 wire-wrap

wire, that works pretty good.

Ron Wanttaja

Comments? Contact Ron Wanttaja.

Return

to The Stories Page

Return

to The Stories Page

I bought a

few of these planes, then discovered the new Tyco "Sky Force" line of mini-RC

planes. The interesting thing about these is that the airplanes are

just profile designs (e.g., the fuselage is flat, not three-dimensional)

like my old U-control planes, and the airplane's RC gear is modular.

The receiver and battery are installed in a tiny plastic box that clips

into a special mount on the side of the airplane, and two sets of wires

lead to the motors, which clip onto special mounts on the wings.

The Sky Force sets include one set of RC gear and two airframes...and you

can quickly switch the receiver and motors to the other airframe as you

wish.

I bought a

few of these planes, then discovered the new Tyco "Sky Force" line of mini-RC

planes. The interesting thing about these is that the airplanes are

just profile designs (e.g., the fuselage is flat, not three-dimensional)

like my old U-control planes, and the airplane's RC gear is modular.

The receiver and battery are installed in a tiny plastic box that clips

into a special mount on the side of the airplane, and two sets of wires

lead to the motors, which clip onto special mounts on the wings.

The Sky Force sets include one set of RC gear and two airframes...and you

can quickly switch the receiver and motors to the other airframe as you

wish.