Tach Attack!

Original Posted July 2009

Update posted July 2016 and

updated June 2017

Eventually, I had to bite the

bullet.

I'd been fighting tachometer problems in my Fly Baby since

February. It started out as a major-league shaking of the

needle. I'd pull the drive cable out, lubricate it, and

the tach would work fine on the next flight and be back to its

old tricks the flight after that.

And it got worse. Pretty soon, the tach needle would shake

a while, then just drop down to zero.

That got to be the litany, for about six months. I'd make

a change, and for the next flight or two, the tach would work

perfect. Then the same problems reappeared.

I tried everything, from a new tach (actuall, a borrowed used

one) to a new tach cable. With everything else pretty much

eliminated, the worst-case scenario was about the only one

left: The tachometer drive on the back of the engine was

bad.

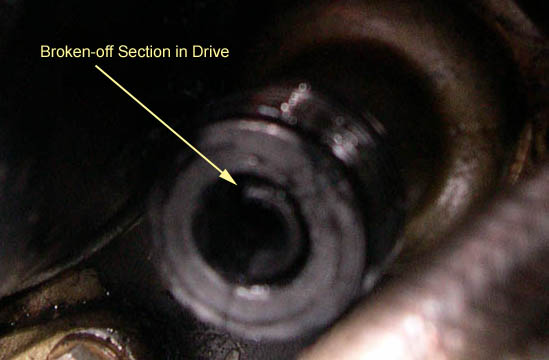

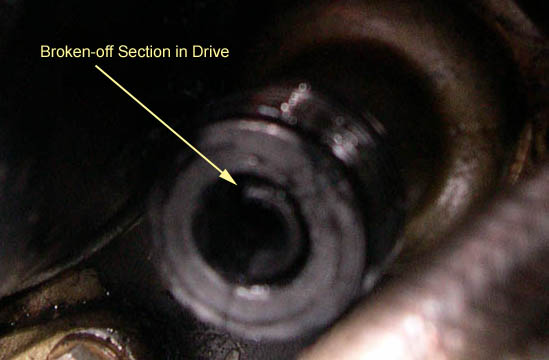

An out-of-focus, grainy digital camera

picture seemed to show the center drive section broken in

half. Problem confirmed.

All right…now what?

My first inclination was to

get the tach drive itself fixed. But the tach drive is

part of the oil pump idler gear, buried in the accessory

case in the back of the engine. I took a few moments

to contemplate what that meant: To replace it, I'd

have to remove the engine from the airplane, remove the

starter, generator, and both magnetos from the back of the

engine, then remove the entire accessory case to get at the

oil pump gears. And, of course, reassemble everything,

with a high preference to having things working properly

when I got done. And, frankly, I'm not really

qualified to break down an engine that far. To have it

done would probably run into a thousand dollars or more.

I started looking into the possiblility of an electronic

tach. It was mostly disappointing. Most installed a

transducer on the engine tach drive...which I figured

wouldn't work in my case, since they probably would have the

same problems with my damaged drive head. Others connected

to a Bendix or Slick magneto...neat option, but I have

Eisemans.

Finally,

I noticed the "Tiny Tach" on the

Aircraft

Spruce

web page. Seemed pretty good...got its signal by

wrapping a wire around a spark plug cable. From the

description, I wasn't completely sure which model to

buy. But when I went to the manufacturer's web page, I

found they had a universal "Commercial" model that also

updated faster than the standard units.

Only $65, so I went ahead and ordered one. It had

both a tach function as well as an hourmeter and two

service timers. It didn't need ANY other connection other

than to wrap the sensor wire around a spark plug cable. It

has a built-in battery.

When it came in, I went to the airport and tried a

temporary installation. No go...tach read zero. I

suspected the shielding on the tach cables, and a call to

the tach vendor confirmed it. The tech recommended peeling

the shielding back near a plug, but I didn't want to run

my tach wire out into the slipstream.

One of my spark plug wires is about 9" too long, and a

previous owner had wrapped up the excess and tie-wrapped

it to the engine mount. I figured I'd modify the

wire there, so if I botched it, there'd still be enough

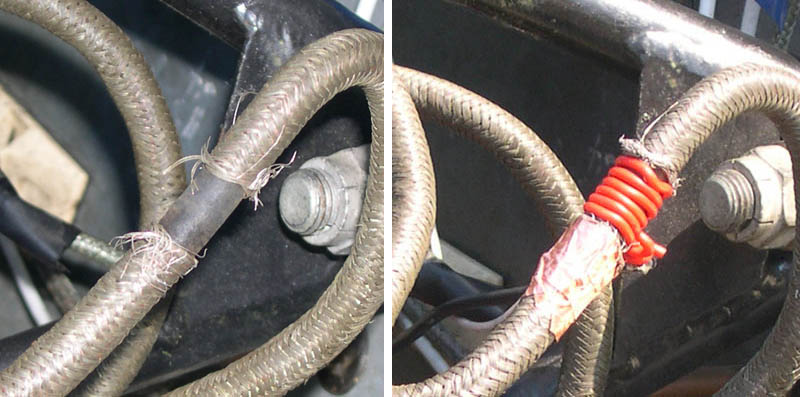

cable to connect to the mag. So I picked at the shielding

with a toothpick to make some openings, then carefully

plucked away at it with an exacto knife. A few minutes

work, and I had a 1" long section of cable free of the

braid. (Note: More-modern plug wires may not

have this external braid!)

The tach instructions said to wrap the red wire around the

cable 3-4 times. The tachometer worked, but the idle was

erratic. I eventually added a couple of extra turns

to make the reading more stable.

I made a mount for the Tiny Tach from some leftover 1/8" plywood.

I could have just used a flat sheet to attach behind the panel,

but I ended up with a "sandwich" construction where the outer face

was circular with the diameter just less than a standard

instrument hole. I felt this gave a lot nicer look to the

installation....it looked more like an instrument sitting "in the

hole" than just a flat sheet behind.

One thing I had to do was plug off the old tach cable port on the

back of the engine. Aircraft Spruce had a cap for Lycomings that

had the same thread sizes, so I took a chance that it'd fit my

Continental.

It did, but the hardest part was safety-wiring it in place. The

cap sits between the generator and the right mag, and there aren't

any good places nearby to connect the safety-wire to. I finally

settled on a fitting eight or so inches away, and fed in a long

piece of safety wire through pre-drilled holes in the end of the

cap.

I was wiggling the wire around, trying to curve the other end back

around, when I heard a crackling sound. I stepped back and saw

smoke rising. The loose end of the safety wire had flipped up and

had shorted a +12V terminal to ground!

Problem solved...but now I had a nice little

burn-blister across the last joint of my middle finger.

Problem solved...but now I had a nice little

burn-blister across the last joint of my middle finger.

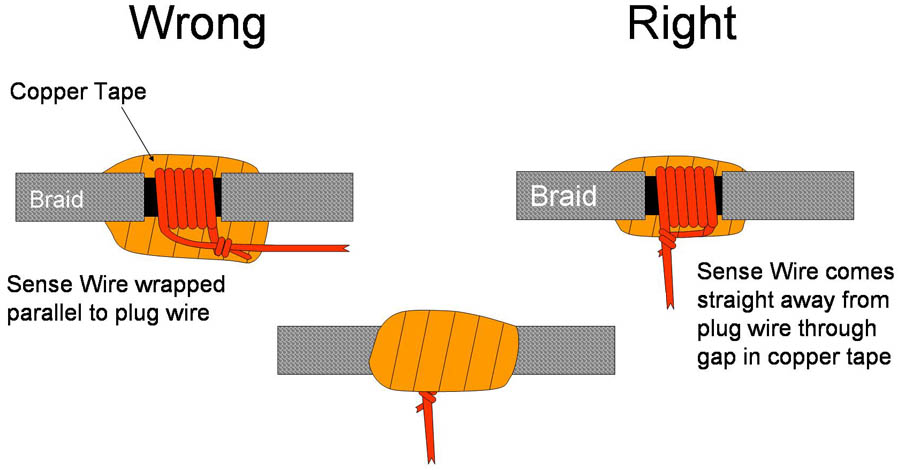

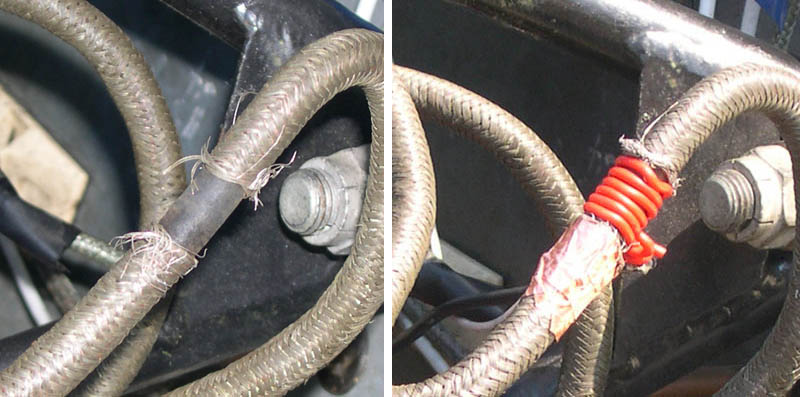

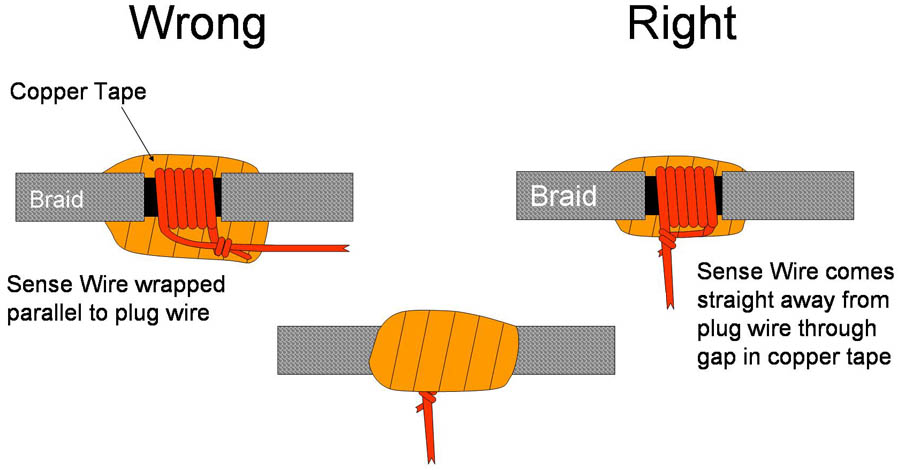

The cap was finally safetied, and I ran the tach wire ran over the

same route as the old tach drive cable. Wrap the red sensor

wire around the open area between the braid four times, then

lay the sensor wire parallel to the spark plug wire and wrap the

whole area in copper tape. I was concerned about the

open braid causing radio noise.

No radio noise...but no operation of the tach, either.

I figured it was the copper tape, so I stripped it away and

straightened the sensor wire. That got things working again.

I'd brought a headset with, and noticed that the open section in the

braid produced only a very minor bit of popping into the

radio. But I'd started to wonder if maybe my copper tape

wrapping HADN'T been the problem, earlier. I had laid the rest

of the sensor wire horizontally along the plug wire under the copper

tape. The diagram from the tach manufacturer shows the sensor

wire coming straight away from the plug wire, instead. So I

re-wrapped the section with copper tape, taking care to let the

sensor go directly away from the plug wire instead of wrapping it in

the copper tape.

And lo and behold, it worked.

I wrapped the area with electrical tape for a bit of

durability. Finally, the loop of spark plug wire was tied back

the way it had been, against a tube of the engine mount with

tie-wraps.

Since it's connected to the left magneto, conventional "Mag checks"

are a thing of the past. When the mag switch goes to "R", the

tach goes to zero...it can't register if the magneto isn't firing.

I don't see this as much of a drawback. I've been less

concerned with the actual RPM drop during a mag check than with

rough running, instead. I figure that any real problem will

manifest itself as missing and stumbling, rather than hitting 155

RPM on a mag drop.

In any case, I own a small handheld tach, and will use it at annual

time to make sure things are hunky-dory.

The hourmeter function is pretty slick; it registers hours until the

engine starts, then automatically switches to the tach mode.

However, the hour meter shows hours and minutes only until the tach

reaches 199:59; after that, it reads whole hours only.

Not a real drawback, as the tach also includes a secondary counter

that can still be used to keep track of minutes. However, 200

hours is about five years of flying for me, and the built-in battery

of the Tiny Tach is only good for 5-8 years. At that point,

I'd better hope the company is still operating...or come up

with some other solution.

Update - July 2016

Well, all good things must come to an end. I installed the

original Tiny-Tach in July 2009, and by late 2014, the display was

starting to get a bit faded.

But...shoot, it still worked. So I ordered another one as a

stand-by, but left the old one in place. Surprisingly, it

held on for another year and a half. Two weeks ago, it was

very, VERY faint (but readable). But by the end of my last

flight, it was completely dead.

Pretty good, really. The company guarantees five years

(which is about when it started to fade), but I got seven years'

service out of it.

First decision was whether to install the one I'd ordered

earlier. They were good for five years, and this one had

already used up almost two years of life.

I decided to make life easier and install a connector at the

spark-plug-wire-wrap. That way, I figured, I could just

quickly set up and install a new one if this one goes bad.

Plans shattered with trying to run the cable for the new

tach. I could NOT get it to feed from the cockpit. I

eventually had to remove the top cover forward of the cockpit to

get access to the run. With that, though, it was easy.

Super easy to finish the run, here.

But when I got things forward, I started to re-think the connector

idea. Replacement of the Tiny Tach wasn't going to be as

simple as I desired. Why take a chance on the connector

messing things up totally.

As it turned out the old plug-wire wrap was easy to remove.

The new one was easy to apply, but for some reason, the gauge didn't

work!

Not sure what happened. Maybe the application of the copper

tape interfered with it. Or...maybe the Tiny Tach design had

changed a bit. I tore everything open again, and started from

scratch...and found I needed only half the number of wire turns I'd

had before. The instructions caution that too MANY turns can

cause issues. Don't know if it was just my installation, or

the new gauge is more sensitive.

In any case, the fewer turns appear to have done the trick.

It's working now.

On Tiny Tach Battery Replacement

(added June 2017)

I had originally intended to cut open the old Tiny Tach and

investigate methods of making the battery replaceable.

Decided against it for one main reason: As I mention above,

when the hourmeter on the tach passes 200 hours, it counts ONLY

whole hours rather than hours and minutes. Frankly, that's of

little use to me, and my tach had enough hours that I'd have to deal

with it in a year or so.

I do have an old Hobbs meter; considered using that to keep track of

hours instead. But I like the cleaner approach of just

replacing the whole unit.

Return to the Tech Page

Return to the Tech Page

An out-of-focus, grainy digital camera

picture seemed to show the center drive section broken in

half. Problem confirmed.

An out-of-focus, grainy digital camera

picture seemed to show the center drive section broken in

half. Problem confirmed. Finally,

I noticed the "Tiny Tach" on the Aircraft

Spruce

web page. Seemed pretty good...got its signal by

wrapping a wire around a spark plug cable. From the

description, I wasn't completely sure which model to

buy. But when I went to the manufacturer's web page, I

found they had a universal "Commercial" model that also

updated faster than the standard units.

Finally,

I noticed the "Tiny Tach" on the Aircraft

Spruce

web page. Seemed pretty good...got its signal by

wrapping a wire around a spark plug cable. From the

description, I wasn't completely sure which model to

buy. But when I went to the manufacturer's web page, I

found they had a universal "Commercial" model that also

updated faster than the standard units.

Problem solved...but now I had a nice little

burn-blister across the last joint of my middle finger.

Problem solved...but now I had a nice little

burn-blister across the last joint of my middle finger.

Return to the Tech Page

Return to the Tech Page